3D Print

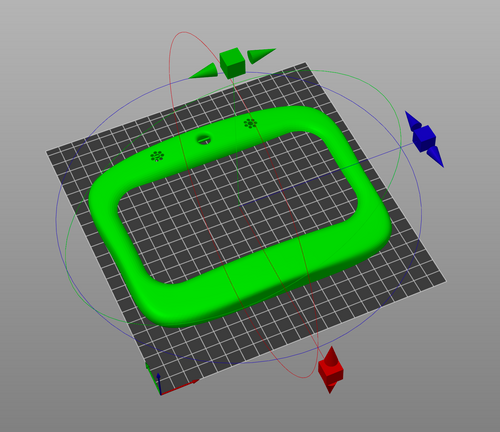

Prints should be printed with the flat part towards the bed with supports enabled as shown here.

Face Front

Print one of this file: Face Front

Face Back

Print one of this file: Face Back

Tiara (Optional)

To have a removable headpiece (e.g., to personalize your robot with hair), print one of this file: Tiara

The piece attaches to the top of Shutter's head with magnets.

Face Material

Nylon is the optimal material for these 3D printed parts. We have achieved the best looking, strongest prints using a carbon fiber filled nylon. The downside of using Nylon is that it requires a temperature at the higher range possible on consumer grade 3D printers (300 deg. C). Do not print Nylon on your printer if you have a hot end with a PTFE liner as PTFE degrades and releases toxic fumes at these high temperatures. Instead, you will need an all-metal hot end to print Nylon.

ASA has also been tested. ASA is one of the most temperature resistant materials, so it will not soften in moderately warm conditions. It is also easily post-processed (sanded), however, it is difficult to print with as it tends to warp during printing unless a very warm (110 deg C) heated bed is used inside of an enclosure. Depending on your setup, much sanding may be necessary to achieve a high quality finished print.

While it is possible to print the face using PLA, the low temperature resistance of PLA means that the face may start to distort if it is left in a hot room or direct sunlight. Therefore, we suggest you avoid using PLA.

Another alternative material is PETg, which is slightly more temperature resistant than PLA, so it is easier to print and will not soften moderately warm conditions. However, PETg is very difficult to post process (sanding is very difficult) and therefore print quality may vary depending on your printer.

Bumpers

Print two of this file: Bumper

Bumper Material

We used TPU so that the bumpers would be flexible enough.

Build Your Own Shutter Robot

- Laser Cut Pieces

- Water Jet Pieces

- 3D Printed Pieces

- 1. Set up Servos

- 2. Assemble Base

- 3. Assemble Arm

- 4. Assemble Head

- 5. Build E-Stop

- 6. Final Assembly

Gather Your Materials

Bill of MaterialsAssemble Your Robot

Install and Run the Software

Software Setup